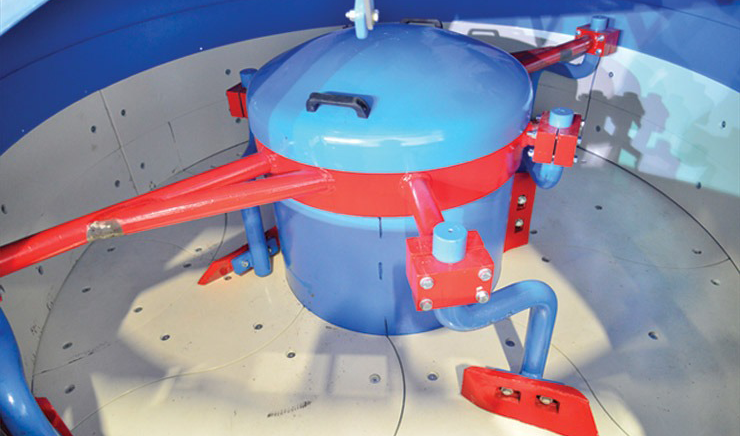

PAN-1000

1500/1000 PAN MIXER

45 KW power. Fast and excellent quality mixing.

MIXER ARMS AND BLADES

- Mixer arms can be easily adjusted downward as they wear.

- Mixer arms and blades can be easily replaced.

- Mixer blades are made of Ni-hard quality castings and have a hardness of 54 Hrc. They are as hard as they cannot be processed and as flexible as they will not break.

- The mixer blades, designed for perfect mixing based on decades of experience, are highly durable against breakage, made of special flexible steel to prevent issues when mixing zero-slump concrete.

WEAR PLATES

- Base and side wear plates are optionally made of Ni-hard hard castings or Hardox quality steel sheets.

- Standard holes can be easily replaced.

- Plate dimensions are calculated for easy transportation and replacement.

REDUCER

- One of the most important elements in the mixer is the reducer. Our reducers are of the Italian COBRA brand, widely used by many European mixer manufacturers. These are high-quality, long-lasting reducers developed with years of experience, making them highly durable.

- Motors are ABB brand, low-energy class motors, contributing to continuous energy savings and a shorter payback period as the mixers operate.

- An advantage of our mixers over competitors is the use of a higher-grade motor and reducer. The capacities of all mixers on the market are calculated and manufactured according to the fresh concrete. However, Milano Mixer is designed to easily mix the very challenging “zero-slump” consistency. It is specifically designed for companies producing prefabricated concrete elements, interlocking paving stones, and similar products that require easy mixing of a challenging consistency.

DESIGN

- Our mixers are designed for use in all types of concrete plants.

DISCHARGE

- The discharge lid is designed to open to its maximum extent.

- The size and design of the discharge lid and blades are designed for fast discharge. There is also a manual lever pump in the hydraulic system to open the mixer lid in case of power outages. The piston and bearing structure is designed to easily and smoothly open and close the discharge lid.

MAINTENANCE and MONITORING SYSTEM

- Maintenance and monitoring covers are equipped with a safety switch system, prioritizing worker safety.

SAMPLE TAKING LID

- Optional and can be easily mounted when requested, a blind cover is left on the body for this purpose.

QUICK DISCHARGE SYSTEM

- Optional and can be mounted, a system that allows the mixer to be emptied very quickly.

WASHING SYSTEM

- Optional pump-nozzle system for easier and faster cleaning of blades.

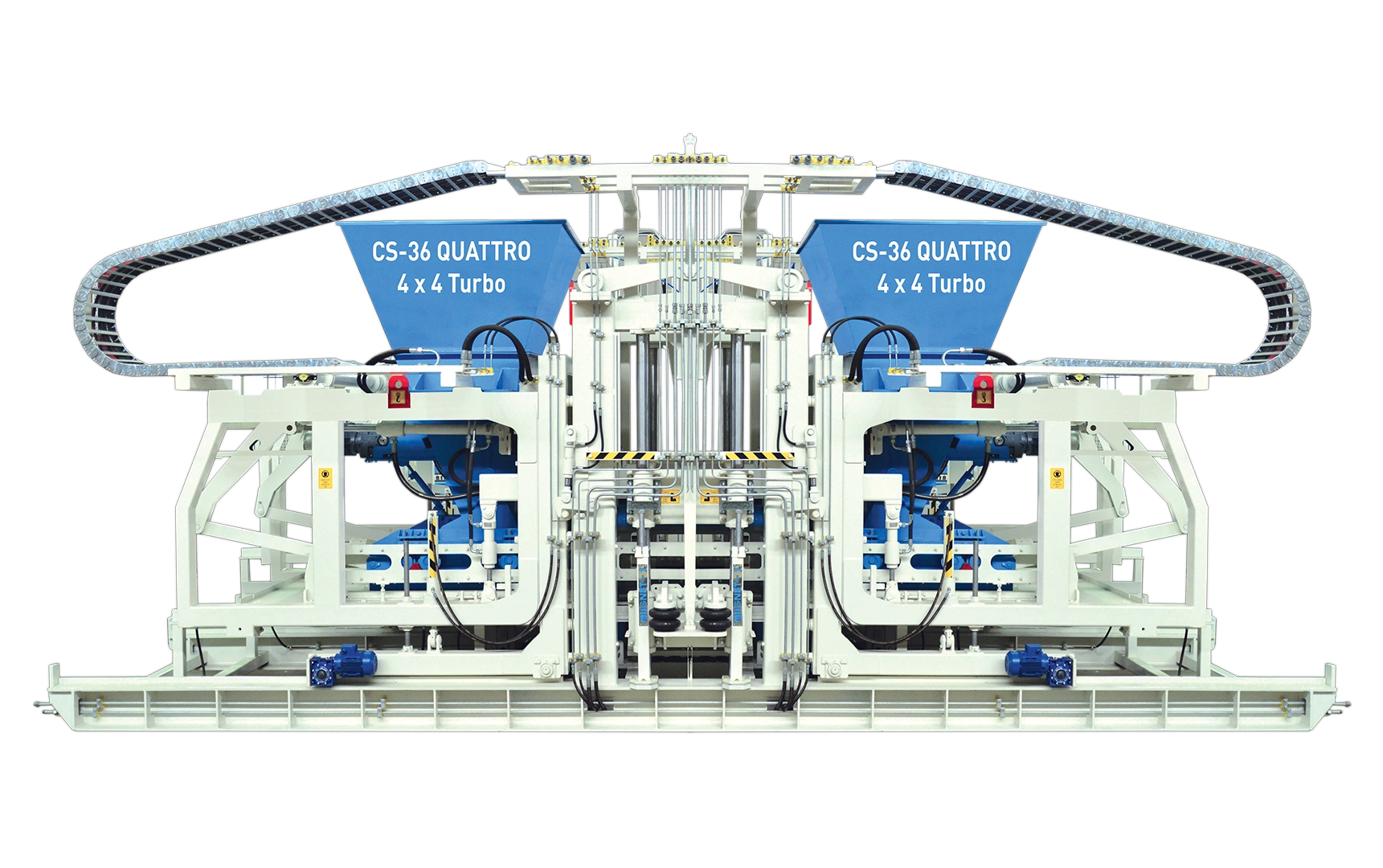

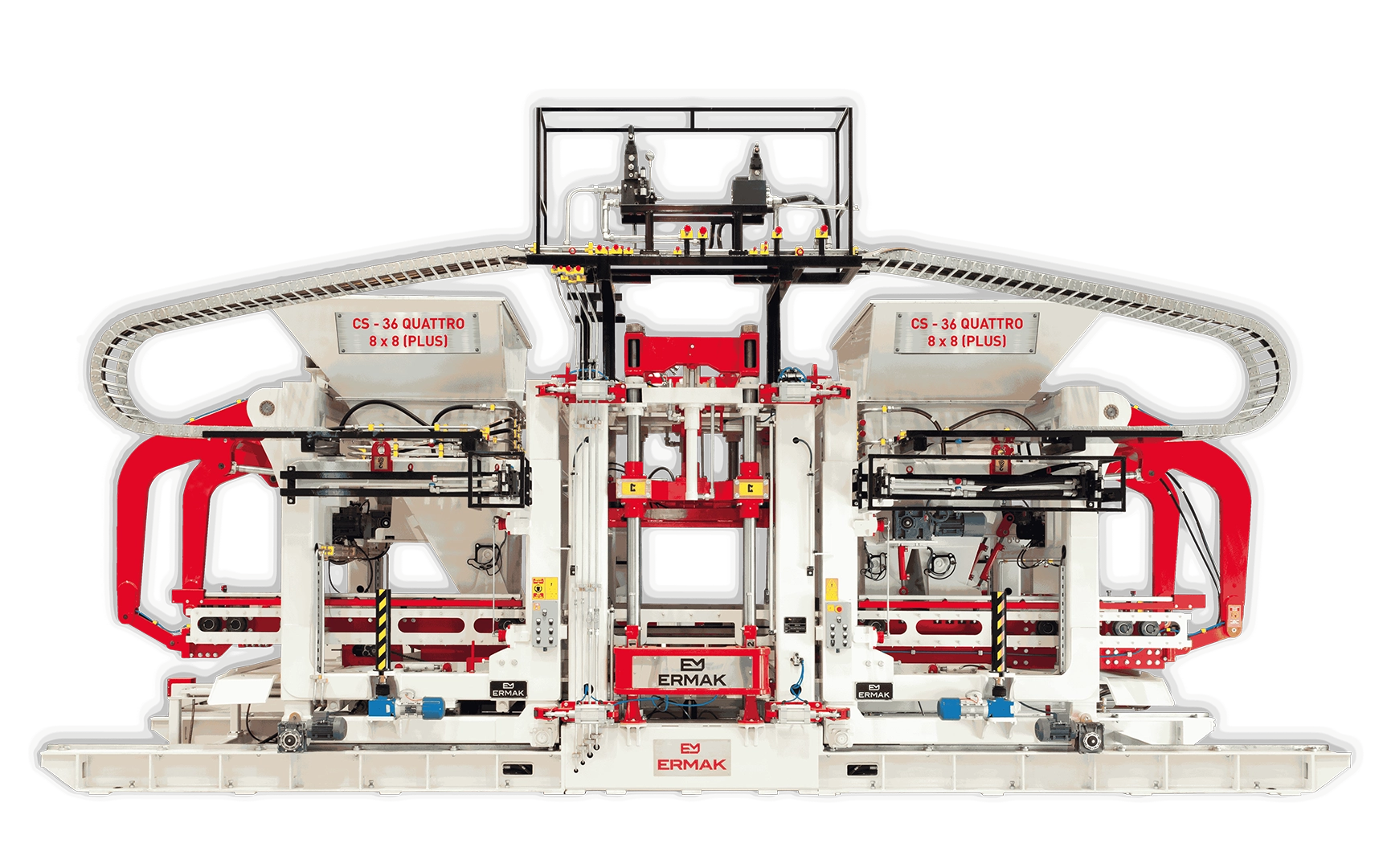

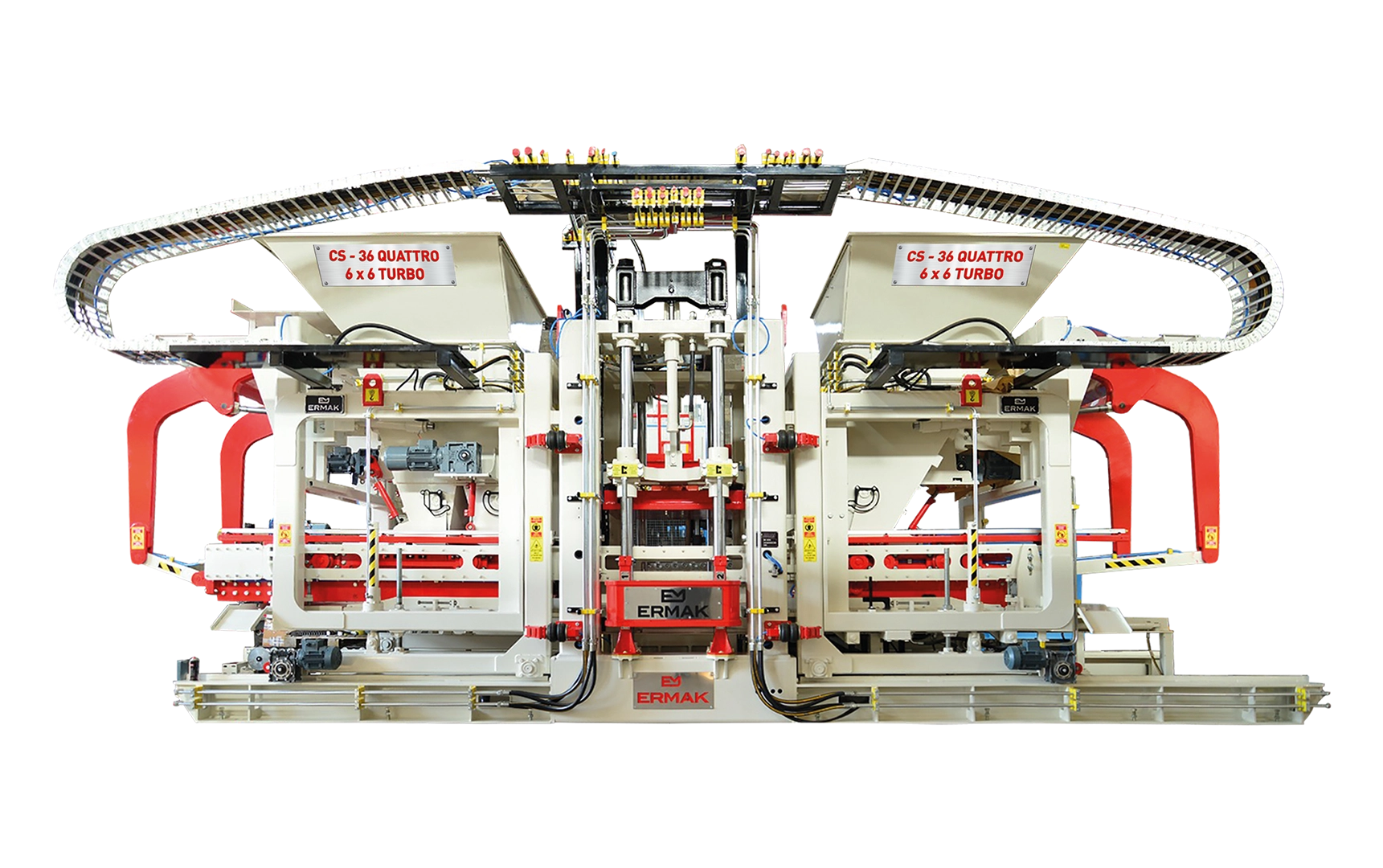

Product Gallery

Product Features

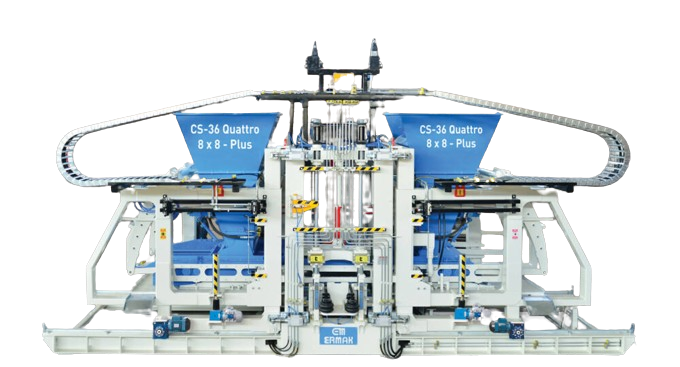

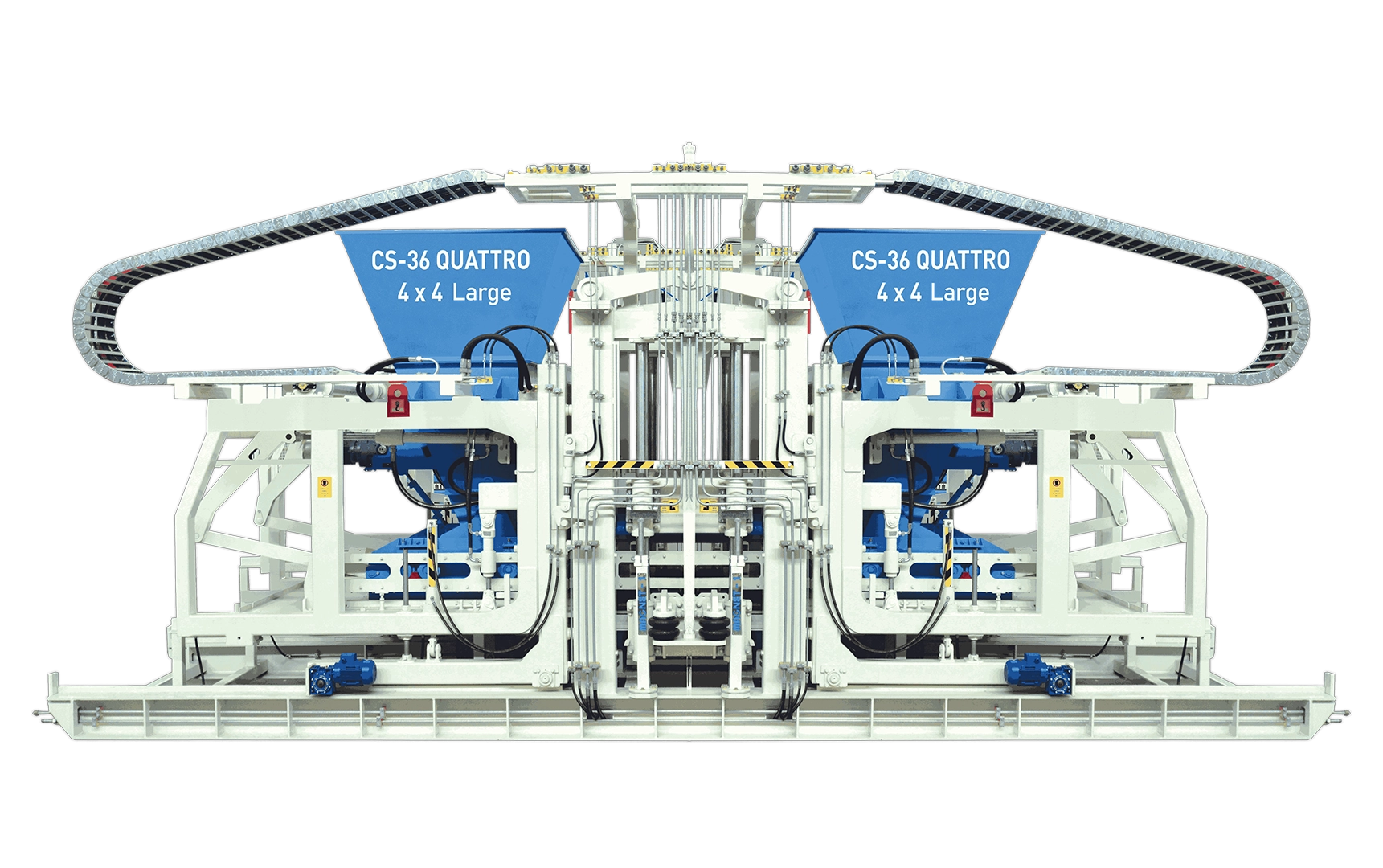

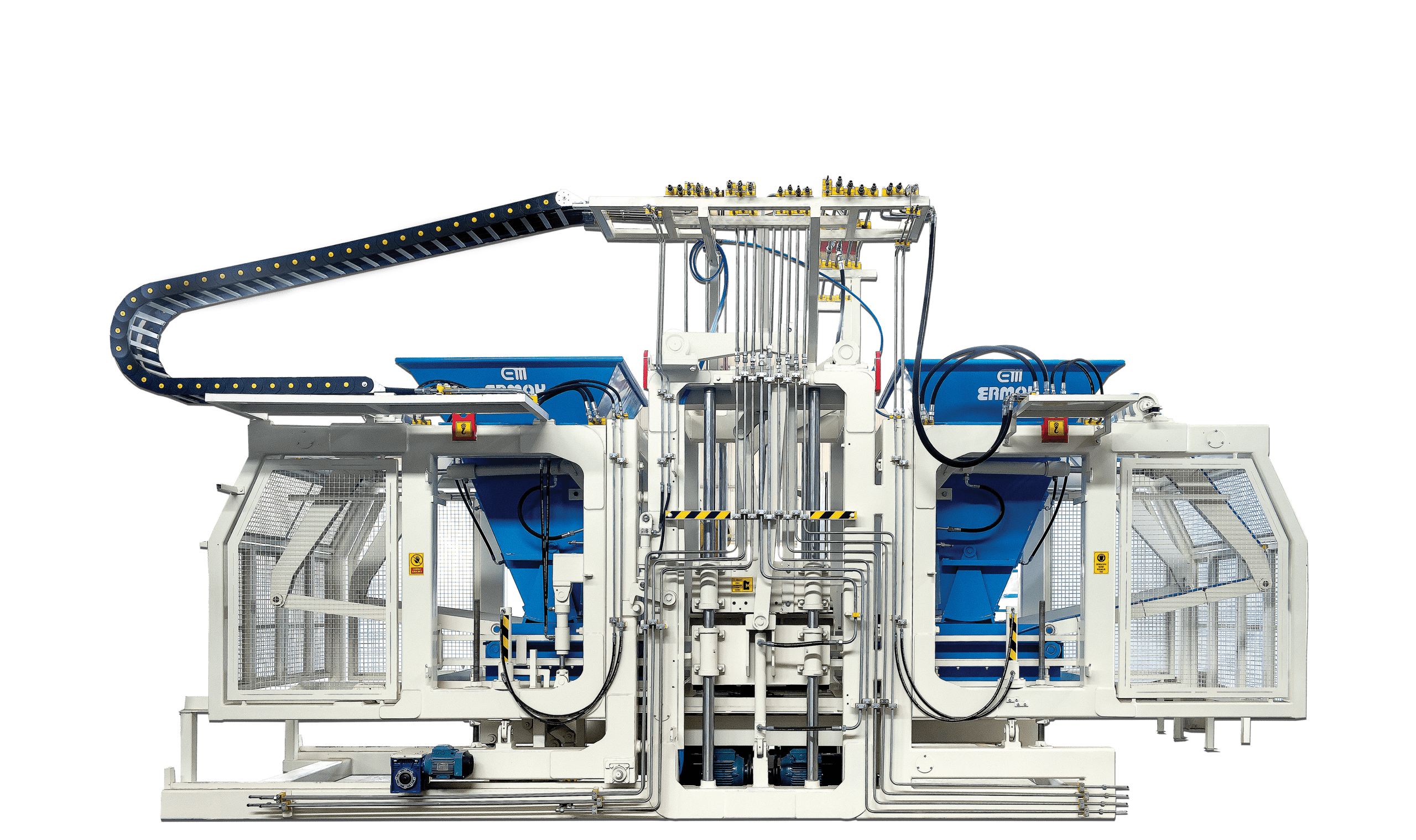

ERMAK MAKİNE

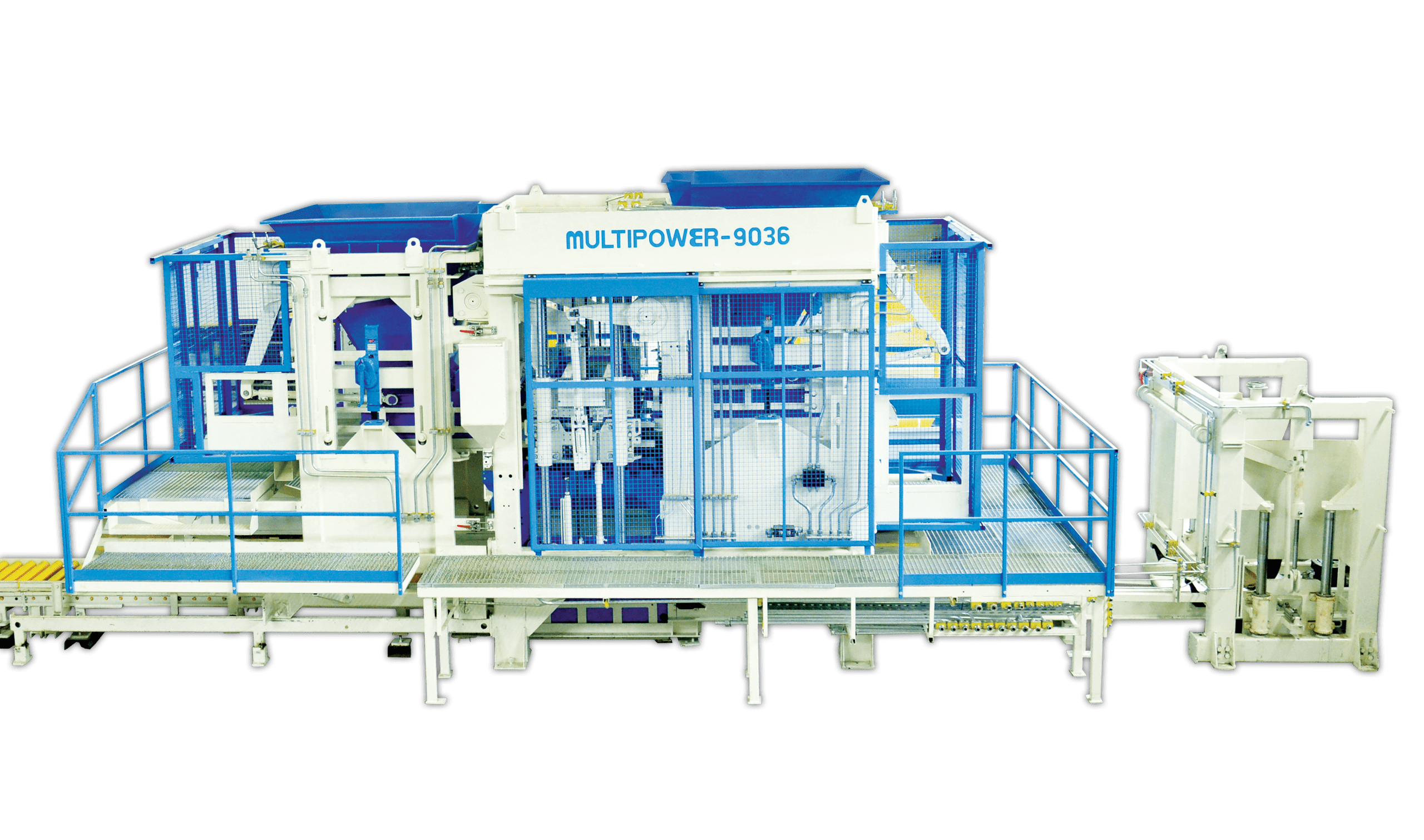

Other Products